Detailed explanation of the production and processing process of PCB circuit boards in the factory

Time:

2022-05-07 14:11

Source:

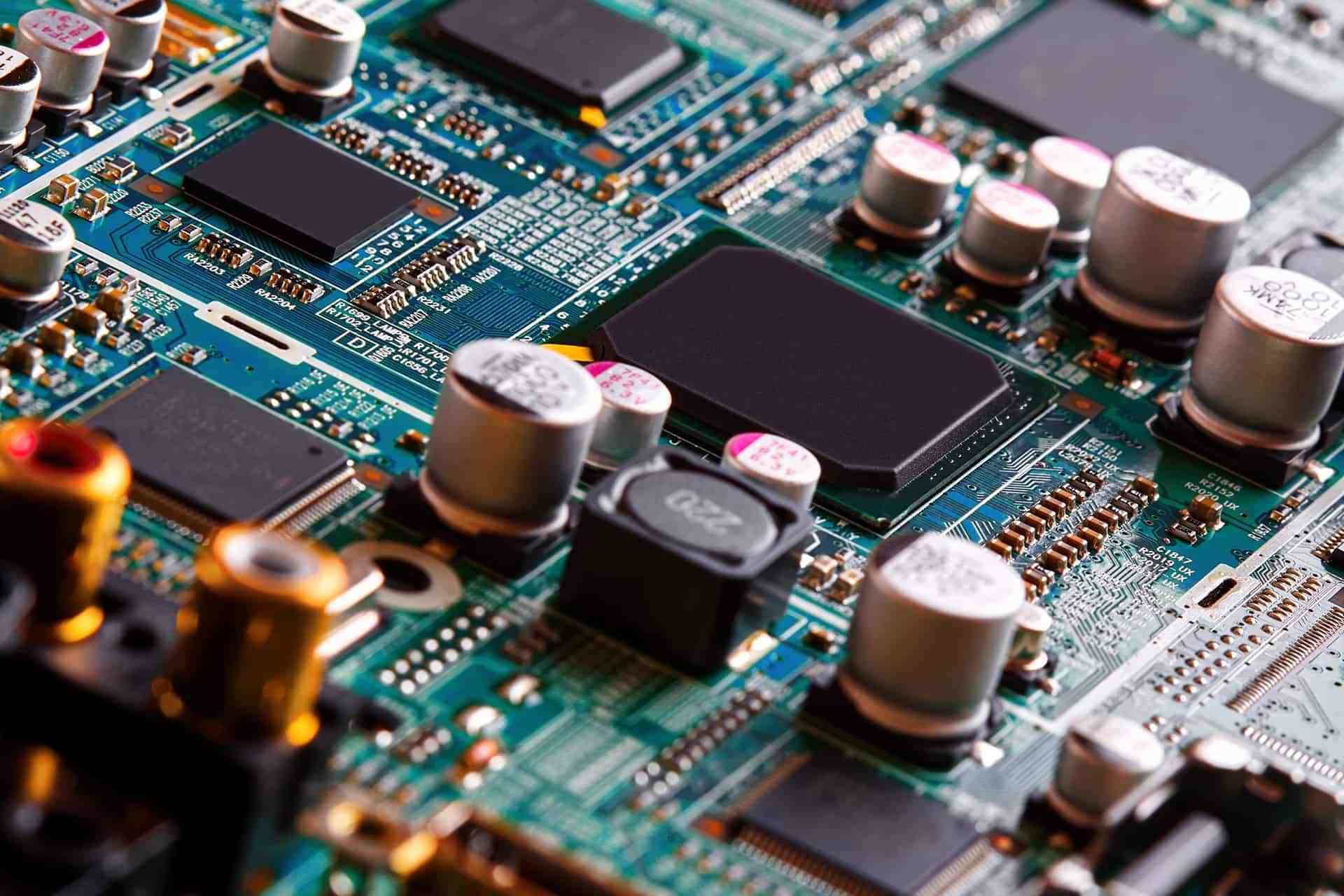

[Inner layer line] The copper foil substrate is cut to the size suitable for processing and production. Before the film is laminated, the copper foil on the board usually needs to be roughened by brushing, micro-etching, etc., and then the dry film photoresist is adhered to it at a suitable temperature and pressure. The substrate with the dry film photoresist is sent to the UV exposure machine for exposure. When the light-transmitting area of the negative film is irradiated by ultraviolet radiation, the photoresist will polymerize, and the line pattern on the negative film will be moved to the dry film on the flat surface. photoresist. After tearing the protective film on the surface of the protective film, first use a sodium carbonate aqueous solution to develop and remove the opaque part on the film surface, and then use a hydrogen peroxide mixed solution to remove the exposed copper foil corrosion to form a line. Finally, the dry film photoresist is washed off again with an aqueous solution of lightly oxidized sodium.

[Lamination] The inner circuit board after completion must be bonded to the outer conductor with glass fiber resin film. Before lamination, the inner layer board needs to undergo blackening (oxygen) treatment to passivate the copper surface to improve insulation, and to roughen the copper surface of the inner layer circuit to obtain good adhesion to the film. When riveting, riveting is performed on the six-layer circuit board first, and then the inner-layer circuit board is superimposed with a riveting machine. It is then neatly stacked between the mirror steel plates with a tray, and sent to a vacuum pressing machine to harden and bond the film with appropriate temperature and pressure. On the X-ray automatic positioning drill target, the circuit board after pressing is used as a reference hole for internal and external line alignment. And the edge of the board is properly and finely cut to facilitate subsequent processing.

Drill the circuit board into the via holes of the layer circuit and the fixing holes of the soldering parts with a CNC drilling machine. The circuit board is mounted with a horizontal bottom plate (phenolic resin board or wood pulp board) on the drilling machine table, and a pin (aluminum board) is inserted on the drilling machine table to reduce the appearance of the drill bit.

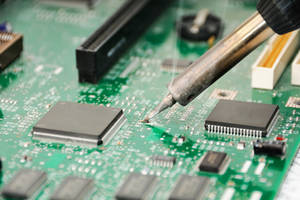

[Plated through hole] After the interlayer via hole is formed, a metal copper layer needs to be laid on it to complete the conduction of the interlayer circuit. First, use heavier sanding and high-pressure cleaning methods to clean the hair on the hole and the powder in the hole, and attach tin powder to the cleaning hole wall.

[Primary copper] palladium glue layer, and then reduce it to metal palladium. The circuit board is immersed in chemical copper solution, and with the help of the catalytic action of palladium metal, copper ions in the solution are reduced and deposited on the hole wall to form a through-hole circuit. The copper sulfate plating method is also used to thicken the copper layer in the via hole, which is sufficient to resist the impact of subsequent processing and use environment.

[Secondary copper wire for external line] It is like moving the wire on the manufacturing line, and it is divided into positive and negative production methods on the online etching. The production method of the negative sheet is the same as that of the inner layer line method. After the development, the copper is directly etched, and the film is removed. The positive film method is to add secondary copper and tin-lead plating after developing (the tin-lead in this part will be reserved as an etching resist in the subsequent copper etching process), and then use alkaline ammonia water and copper chloride. The mixed solution corrodes and removes the exposed copper foil to form a circuit. Finally, the tin-lead layer that has been successfully retired is peeled off (in the early days, the tin-lead layer was retained, and it was heavily used to wrap the circuit as a protective layer).

[Solder Resist Ink Printing] Earlier green paints were produced by screen printing and then hardening the paint film by thermal baking (or UV irradiation). However, due to the fact that it often causes green paint to penetrate into the copper surface contacts of the circuit terminals during the printing and hardening process, it brings trouble to the welding and use of parts. Now, in addition to the simple and rough circuit boards of wires, more photosensitive green paint is used. Production.

Print the text, trademark or component required by the customer on a flat surface in a screen printing method, and then use thermal baking (or ultraviolet light) to harden the text.

[Contact treatment] Most of the surface of the wire is covered with anti-soldering green paint, only the terminals used for welding, electrical testing and circuit board insertion are exposed. The terminals need an additional appropriate protective layer to avoid oxides on the terminals connected to the anode (+) during long-term use, which will affect the stability of the circuit and cause safety problems.

【Die cutting】The circuit board is cut into the external size required by the customer with a CNC forming machine (or a die punch). During the cutting process, the circuit board is fixed to the bed table (or mold) through the positioning holes that have been drilled before. After cutting, the grinding angle is processed on the gold finger part, which is convenient for the insertion and use of the circuit board. In order to facilitate the user to split the multi-layer linear circuit board after the plug-in type, in order to facilitate the user to split the plug-in. Ultimately washes away powder and surface ionic contaminants from the board.

Relevant news